In the aerospace and defense sectors, performance, precision, and reliability are non-negotiable. Even the smallest particle or environmental fluctuation can compromise mission-critical components such as satellites, missile systems, or laser modules. A cleanroom for aerospace defence industry provides a controlled environment that protects sensitive assemblies from contaminants, electrostatic discharge, and other environmental risks, ensuring optimal performance and reliability in high-stakes operations.

Why Aerospace and Defense Rely on Cleanrooms

Aerospace and defense projects involve components with extremely low tolerance for defects. Airborne particles, humidity variations, static discharge, or micro-vibrations can lead to functional failures. Cleanrooms ensure that production environments meet stringent aerospace cleanroom requirements, allowing sensitive equipment to operate flawlessly under extreme conditions, whether in space, deep-sea defense applications, or desert deployment.

Manufacturers use cleanrooms to:

-

Produce components free from dust and contamination, safeguarding precision parts such as propulsion systems, drones, and optical payloads.

-

Maintain adhesives, coatings, and structural elements in optimal conditions to ensure material integrity and long-term performance.

-

Conduct research and testing in sterile environments to prevent contamination-related failures.

Key Features of Aerospace and Defense Cleanrooms

Particle Control

HEPA and ULPA filtration systems are used to remove particles as small as 0.3 microns, complying with ISO 14644 standards. High-precision aerospace assemblies often require even more stringent control supported by advanced aerospace cleanroom technology.

Precision Environmental Controls

Temperature, humidity, pressure, and airflow are closely monitored and controlled. Even minor fluctuations can affect adhesion, material curing, or calibration of sensitive devices such as solid-state lasers, microelectronics, and satellite instruments.

Electrostatic and Vibration Protection

Anti-static flooring, ESD-compliant workstations, and vibration-dampened structural designs protect sensitive electronics and optical instruments. These measures ensure components meet the reliability standards demanded by aerospace and defense applications.

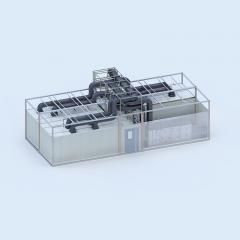

Custom and Modular Cleanroom Solutions

Tailored Designs for Complex Projects

Wonclean delivers fully customized cleanrooms designed to meet specific aerospace and defense requirements. Multi-room layouts may include gowning areas, precision assembly zones, optical calibration areas, and isolated low-vibration chambers. Fire-rated and ESD-compliant materials are integrated to ensure safety and performance.

Modular Aerospace Cleanrooms

Modular designs are increasingly popular due to their flexibility and rapid deployment capability. Benefits include:

-

Shorter construction timelines

-

Easy relocation and expansion

-

Cost predictability

-

Wonclean’s modular cleanrooms can be configured for any cleanliness class, workflow, or equipment integration, making them ideal for evolving aerospace and defense programs.

Industry Applications

Satellite Production and Integration

Satellites require strict particulate control throughout manufacturing—from solar arrays to optical payloads—to ensure long-term operational reliability in orbit.

Missile and Defense Systems

Components such as guidance modules, sensors, laser assemblies, and fuzing systems are assembled in particle-free environments to prevent malfunction or performance degradation.

Deep-Space Launch Vehicles

Rocket structures, propulsion units, and scientific instruments demand ultra-clean conditions to avoid contamination that could compromise mission-critical operations.

Research and Development

Advanced aerospace materials, propellant testing, and quantum defense technologies rely on stable, low-contamination laboratory environments.

Future Trends in Aerospace Cleanrooms

-

Automation and Robotics: Reduce human-induced contamination and support ultra-clean manufacturing.

-

Nanoscale Manufacturing: Higher precision for microelectronics, photonics, and quantum sensors in defense systems.

-

AI-Driven Monitoring: Real-time environmental analysis for airflow, particle levels, and pressure adjustments.

-

Flexible Modular Systems: Modular cleanrooms enable mobile deployment and multi-site aerospace development.

Wonclean Cleanroom Solutions

Wonclean is a leading provider of high-performance cleanroom engineering solutions, specializing in modular systems, softwall structures, isolation enclosures, and advanced contamination-control technologies. With decades of experience and strict engineering standards, Wonclean delivers customized cleanroom environments for aerospace, defense, pharmaceuticals, semiconductors, and other high-precision industries.

In aerospace and defense, where accuracy, reliability, and environmental control are essential, Wonclean’s cleanrooms comply with aerospace cleanroom requirements, supporting satellite production, missile assembly, laser system fabrication, and deep-space mission preparation. By continuously innovating in aerospace cleanroom technology and offering scalable modular aerospace cleanrooms, Wonclean strengthens the global aerospace and defense manufacturing ecosystem.

Servizio online

Servizio online